Industrial Internet of Things: Impact on Manufacturing

The search for the best solutions to stay competitive, be efficient, and grow business is an ongoing effort for all manufacturers.

Leveraging the latest technology in the manufacturing process has allowed companies of all sizes to thrive and compete in the global marketplace.

It is in any company’s best interest and competitive position to choose the most efficient and productive way to manufacture goods.

Companies who rely on traditional or outdated methods instead of taking advantage of newer technologies may struggle to maintain or grow their business.

Driving AI and Analytics

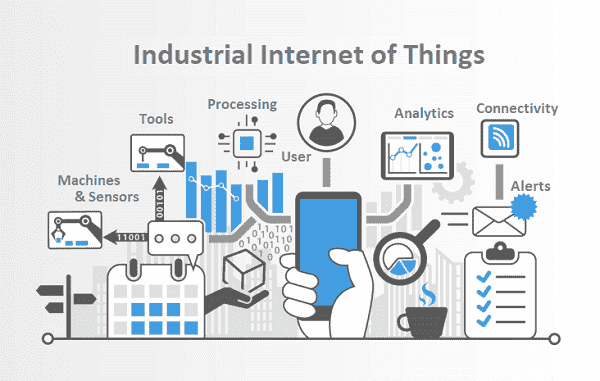

The internet of things, also referred to as Industry 4.0, is a collection of objects, equipment, and devices that are embedded with sensors, electronics, and software and have network connectivity enabling these devices to collect and exchange data.

The industrial IoT “takes networked sensors and intelligent devices and puts those technologies to use directly on the manufacturing floor, collecting data to drive artificial intelligence and predictive analytics,” says Robert Schmid, Deloitte Digital’s chief technologist, IoT.

“In IIoT technology, sensors are attached to physical assets. Those sensors gather data, store it wirelessly, and use analytics and machine learning to take some kind of action.”

Sensors gather data, store it wirelessly, and use analytics and machine learning to take some kind of action.

A key benefit of IIoT is how it can improve operational efficiencies. Such as, when a machine breaks down, connected sensors help determine where the issue has occurred and can prompt a service repair request.

IIoT can also assist with preventative maintenance by predicting when a machine will likely need service or when it’’ near the end of its life cycle before it happens, limiting downtime.

By decreasing machine downtime, companies are able to take better advantage of their businesses capacity and maintain work flow.

IIoT can keep workers safe, warning operators well in advance of a potential catastrophic event allowing them to respond appropriately to the situation.

Increased Pace of Connectivity

The increased pace of connectivity continues with an anticipated 50 billion machines being connected on the internet by 2020.

This trend makes it imperative for manufacturing businesses to adopt these devices and make them an integrated part of their facility operations.

Businesses that take the plunge should be prepared to mitigate the cyber risks in their manufacturing processes and supply chains.

This requires companies to invest time and money on cybersecurity risk management, including the training of employees, building security into devices at the start, and monitoring outside service providers.

IIoT is changing the manufacturing industry with supply chains becoming dynamic, interconnected systems. IIoT technologies are impacting the way products are made and delivered.

And are making manufacturing facilities more efficient, operationally safer, and in many cases saving companies money.

For help in creating sustainable competitive advantages for your business, contact CONNSTEP today (800.266.6672; info@connstep.org).

RELATED

EXPLORE BY CATEGORY

Stay Connected with CBIA News Digests

The latest news and information delivered directly to your inbox.