‘Getting Stronger:’ Five Days on the Manufacturing Road

From Oct. 13-17, business leaders and public officials crisscrossed the state daily visiting the companies, schools, and workforce partners fueling Connecticut’s manufacturing industry.

In a hard-to-miss bus covered in logos and a giant Made in Connecticut stamp, the the CBIA Foundation‘s second annual manufacturing tour logged more than 600 miles along fall-colored highways, main streets, and back roads.

“Connecticut’s manufacturing industry is a critical part of our state’s economy,” said CBIA president and CEO Chris DiPentima.

“We’re bringing more public awareness to our rich manufacturing legacy and the way people are innovating and growing their businesses to support the global economy.”

Produced by the foundation in collaboration with CBIA affiliate CONNSTEP, the tour featured a wide variety of products made in Connecticut.

Those products ranged from devices that power NASA missions, jet engine parts for the U.S. military, colorants used by leading cosmetic companies, luxurious packaging, and the planet’s most sustainable plastics.

Manufacturing Coalition

Kirti Patel, the state’s newly appointed chief manufacturing officer, rode the bus each day, noting that the tour was about much more than just visiting factories and facilities.

“We’re shining a light on what’s possible when our vision, skill, and partnerships come together,” he said. “Connecticut manufacturing is strong—and it’s only getting stronger.”

CONNSTEP president and CEO Beatriz Gutierrez said manufacturing in Connecticut is built on three things: innovation, resilience, and community.

As she visited each of the 20 tour sites, Gutierrez highlighted the new CBIA Manufacturing Coalition, created in partnership with CONNSTEP to help manufacturers address challenges and unify the sector’s voice.

“This coalition comes at a pivotal moment for Connecticut’s manufacturing industry,” she said.

“Amid ongoing labor shortages and supply chain uncertainty, it is strong partnerships like these that will give manufacturers the tools and voice to position the industry to grow and thrive.”

Monday, Oct. 13

At the University of New Haven’s Bergami Center for Science, Technology and Innovation, university president Jens Frederiksen said the state’s workforce is changing and resilience is needed to keep pace.

To do that, he says a new 130,000-square-foot innovation center on campus will soon feature employer partnerships that give UNH students real-world experience.

“Our new Research and Development Park will serve as a focal point for private industries to engage the university on an entirely new level,” he notes.

“By establishing a physical presence on campus, companies will have direct access to students, research, and innovation in a manner that will inspire new opportunities and untapped synergies.”

“We are putting ourselves at the forefront of bridging higher education and industry to educate graduates who are better than ready to excel in the global workforce of the future,” adds Paul Lavoie, the school’s vice president of innovation and applied technology.

At Nucor Steel in Wallingford, president Joe Padgett says “the heart of our business is not machinery, it’s our people—and we’re on a journey to become the safest steel company in the world.”

“There’s a lot of appetite for manufacturing jobs because they’re good-paying jobs.”

Over the past three years, Padgett says median annual compensation for Nucor employees, excluding executives, has exceeded $115,000.

Nucor is the largest steel and steel products manufacturer and recycler in North America, with residential construction accounting for the majority of the company’s Connecticut’s business.

The company employs 82 people in Connecticut and recycles steel into more than 300 products, including mesh sheets, rebar, and drawn wiring.

At Microboard Processing, Inc. in Seymour, the company has produced high-reliability printed circuit board assemblies for more than 40 years.

One of the nation’s leading high-tech contract manufacturers, Microboard also builds life-saving portable defibrillators, gunshot detection systems, and mission-critical Department of Defense technologies.

The boards are so sensitive to damage, electrical grounding strips are applied to the bottoms of all shoes to prevent static electricity.

Most board components are so small they’re delivered to the company embedded in film and wrapped around reels—some can actually be inhaled without proper precautions.

The company’s mission-based model also sets it apart, as it donates 100% of its profits annually to global efforts like clean water access, education for vulnerable children, economic empowerment for widows and single mothers, and peacemaking in Africa, India, and Nigeria.

Marion Manufacturing in Cheshire is a contract manufacturer of metal stamped goods for multiple industries, including paper binder clips, automotive parts, medical and aerospace parts.

The company has been in business for 79 years and has continually expanded, moving from Marion Road to its current location on Reinhard Road in 1999.

The average age of Marion Manufacturing’s 28-person team is 38, with nearly half the employees aged between 18 and 29 years old, and two of the youngest are siblings.

“We’ve been fortunate with the talent and insights this youth brings to our operations,” said owner and president Doug Johnson.

“My workforce—especially the younger generation—is impressively well-educated and well-rounded. The skills they bring straight out of high school are remarkable, and they’re ready to contribute from day one.”

Tuesday, Oct. 14

Miyoshi America, Inc. sits in the Dayville section of Killingly and develops and makes surface-treated pigments and mineral substrates for the cosmetics and personal care industry.

It is part of Miyoshi Kasei, a family-owned company with additional operations in Japan, Europe, and China, and its customers include high-end brands like L’Oréal, Chanel, and Estée Lauder.

With 61 employees, Miyoshi America has operated in Connecticut for 40 years, focusing on innovation, sustainability, and production capacity.

Behind its state-of-the-art, 87,000-square-foot facility sits a 2,160 panel solar array that produces 862Kw of energy, supplying 45% of the site’s energy needs.

While the company pledged to reduce its carbon footprint 50% by 2030, as of this year, it stands at negative 57%.

Along a railroad line in Putnam, Impact Plastics produces custom extruded plastic sheet materials designed for food, medical, automotive, and consumer goods packaging—all with a focus on innovation and sustainability.

You can see the materials when you buy a four-pack of Starbuck’s cake pops, certain grocery store yogurt packs, or perfume and cosmetic gift sets with perfectly formed plastic shells to keep items in place.

In addition to using solar power, energy-efficient systems, and recycling programs, Impact Plastics has developed a new, patented material called XPP—a fully recyclable, mono-material alternative to the legacy resins found in most plastics, including single-use water bottles.

“Connecticut has been an ideal home for our business,” says president and CEO David Kingeter. “Its proximity to our key markets, combined with a dedicated workforce, access to clean energy, sustainability initiatives, and a reliable rail infrastructure has allowed us to thrive here.”

At Quinebaug Valley Community College in Danielson, students can get both the basic educational and hands-on manufacturing experience they need to work at leading nearby employers like General Dynamics Electric Boat—for free.

At the school’s 11,000-square-foot Advanced Manufacturing Technology Center, director Steve LaPointe said most college-age students still don’t know about the free, two-year, 60-credit opportunities at their doorsteps.

In response to student and employer needs, Quinebaug now offers two-semester certificate programs in Advanced Manufacturing Machine Technology and Mechatronics Automation Technician.

The certifications can open the door to full-time jobs that pay $55,000-65,000 a year, and still allow students the opportunity to pursue degrees at night.

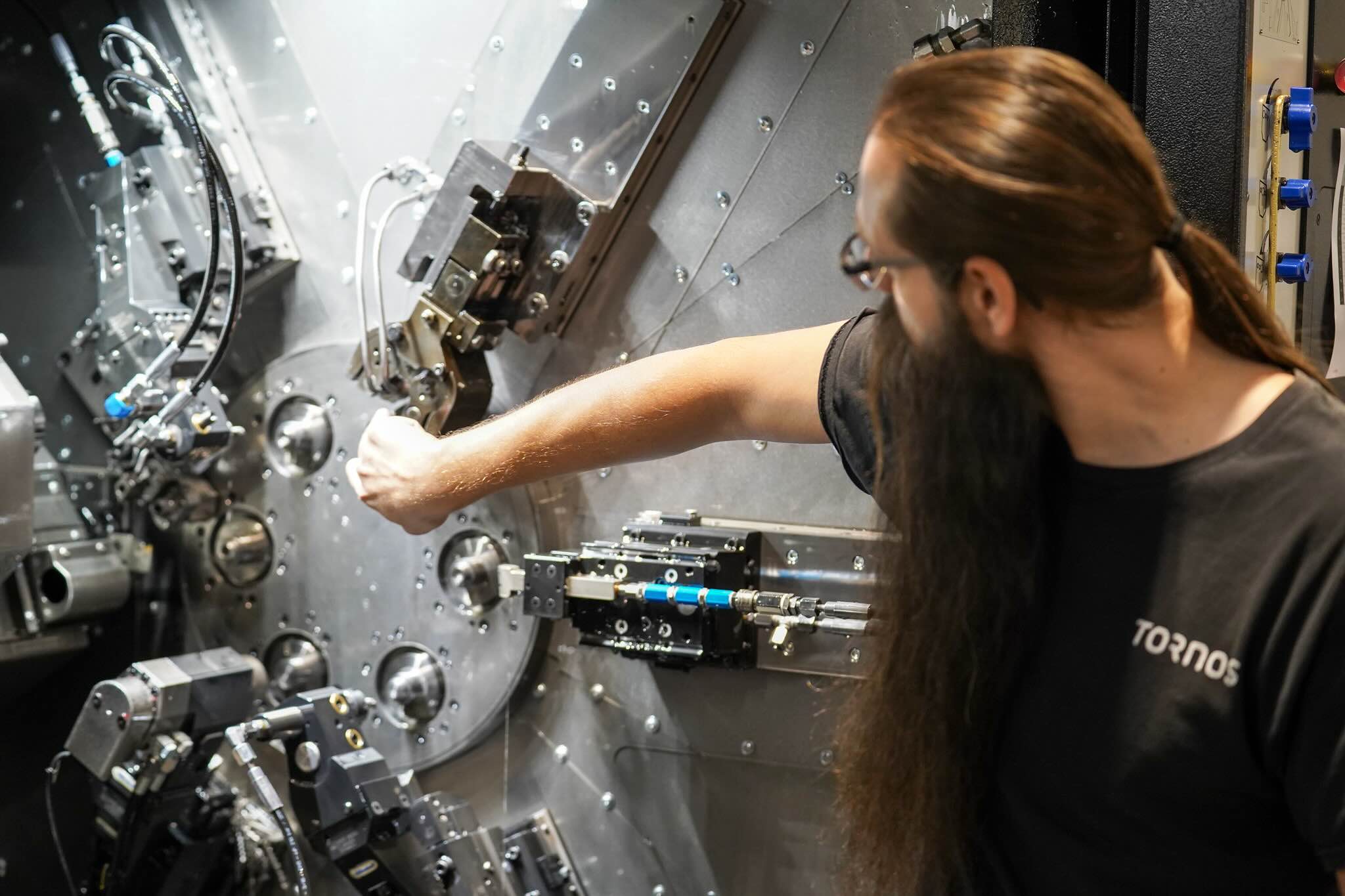

The center also provides continuous levels of advanced CNC training, specifically to help Electric Boat find qualified employees who have skills like blueprint reading, machine operation, programming, and safe working practices.

Kaizen is the word on everyone’s lips at Pursuit Aerospace, where more than 800 employees make aircraft component parts at its 85,000-square-foot headquarters in Eastford and additional facilities in Manchester, South Windsor, Plainville, and Farmington.

The shop floors are full of process improvement examples that reflect the Kaizen philosophy, which follows the Toyota Production System method of continuously evolving and challenging traditional manufacturing methods.

And a program with nearby Brooklyn Correctional Institution supplements Eastford’s second shift, preparing inmates with second chance opportunities for when they are released.

Born from a 2023 merger between Whitcraft and Paradigm Precision, Pursuit Aerospace has grown into 20 businesses worldwide and is the world’s largest privately held aircraft engine component manufacturer.

“We are supported by the partnerships we have with innovative technical schools such as the Connecticut state and community school system, and also the highly skilled and talented workforce that makes up Aerospace Alley,” says executive vice president Jacqueline Ruggiero.

Wednesday, Oct. 15

The Metallica T-shirt that Asnuntuck Community College instructor Mike Kunze was wearing when he greeted the manufacturing tour bus at the Enfield campus had a special meaning.

Asnuntuck has received $125,000 in grants over the last two years through a scholarship program created by the heavy metal band to address issues it faced finding qualified technical crew members.

“The scholarship money has paid for every student’s personal protective equipment, all their books, toolboxes, multimeters and robotics, welding gear—everything,” Kunze explained.

Grants are a key component to Asnuntuck’s advanced manufacturing program, which offers free courses in machine technology, robotics and mechatronics, and welding and fabrication technology.

The school also offers credit programs for high school students to enter pathways leading to associate and bachelor’s degrees, as well as customizable incumbent worker training classes to upskill and meet current business needs.

At AeroGear, Inc. in Windsor, founder Doug Rose talked about how he brought a world-renowned Kaizen expert to Connecticut to learn about Lean manufacturing techniques.

That was in 2003, and Rose explained that he couldn’t afford to bring the consultant to his company alone, so he coordinated a visit for several small aerospace companies and they all split the cost.

“I even had him over for Easter dinner,” Rose said. “It was a life-changing experience, and it’s all about collaboration.”

Founded 40 years ago, AeroGear has expanded five times in Connecticut, and president Frank Rose says the company has expanded from aerospace gear-grinding to full gearbox assembly and gear systems integration.

“We’re a small company that makes a large global impact with the products we offer,” he said. “Our products are on thousands of commercial airline flights a day and on every Black Hawk helicopter in operation.”

At Ensign-Bickford Aerospace & Defense Company in Simsbury, the tour group got an up-close look at the frangible joint, the Coolest Thing Made in Connecticut for 2025—as chosen by Connecticut residents.

The frangible joint is a key component in NASA space missions, with a fully-contained tube of explosives inside that allow rocket stages to separate.

“We were really excited about winning,” said Edris Raji, EBAD’s interim president.

“Chocolate is delicious, but not as cool as our frangible joint,” he added, giving a nod to the competition’s runner-up, Munson’s Chocolates of Bolton.

Company employees throughout the high-tech, highly automated campus gave brief, hands-on and visual presentations showcasing the products they’ve produced for more than 185 years.

“Connecticut is the ideal place for EBAD to grow because it allows us to create high-tech, well-paying jobs while building products that will always be essential for space exploration and national defense,” Raji said.

At HABCO Industries LLC in Glastonbury, president and CEO Brian Montanari says that when you see aircraft in the sky, you’re likely also seeing hundreds—if not thousands—of parts made by his employees.

“For a business of our size, with 55 employees, the outreach that we have, of all the things that we touch in the aerospace industry, it’s pretty unique, and it’s something that I’m pretty excited about,” Montanari says.

Celebrating 55 years in Connecticut this year, HABCO Industries manufactures ground support equipment and test stands for commercial and military aircraft as well as fuel cell and power generation customers.

HABCO serves over 250 customers in 50 countries and has expanded its ability to meet growing demand by cross training employees and having “a never say no approach.”

“Having our business in Connecticut is a strategic advantage,” Montanari adds. “With three of our top four customers right here in the state, we’re positioned close to our key partners.”

Thursday, Oct. 16

The students and faculty at Danbury High School—New England’s largest, with 3,500 students—generate pure enthusiasm and career-ready focus.

“This school runs like a city,” says principal Dan Donovan.

“Thirty-five hundred kids in a building is a lot, so we run smaller learning communities of 450 to 550 students on a team.”

The school has adopted an academy model, including the Art, Engineering, and Design Academy that offers career-connected pathways in applied engineering, computer integrated manufacturing, and art, architecture, and design.

“One of the best things about the academies is that you can try something and see if you like it,” says AED junior Ella Carlino.

At Curtis Packaging in Sandy Hook, you can’t take photos of the company’s soon-to-launch products, but you can touch them.

A $5.4 million, 10-color Koenig & Bauer printing press—the first of its type in the world—is central to the company’s innovative packaging, highlighted by deep colors and rich textures.

In business since 1845, the company’s 130 employees design and manufacture environmentally friendly, luxury folding cartons for a number of leading consumer brands, including Estée Lauder, Origins, Jack Daniels, Grey Goose, Titleist, and Lindt.

“We’ve invested $26 million in capital over the past six years,” says president and CEO Don Droppo.

Focused on environmental responsibility, Curtis became the first carbon neutral packaging company in North America in 2003, using 100% renewable energy, carbon neutral, and zero waste landfill facilities.

OEM Controls, Inc. in Shelton is addressing Connecticut’s housing shortage with an innovative approach—its own housing development.

With just over 200 employees, OEM Controls manufactures a wide range of products, including joystick controllers, multi-grip handles, microprocessor-based logic controllers, rotary switches, and foot pedals.

“We’re trying to attract talent with a lower cost of housing—not just for ourselves, but for other employers in the area, too,” says company co-president Brian “Sam” Simons.

The 120-unit, one and two bedroom apartment development is proposed for a site on property owned by OEM and would feature amenities such as a gym, day care, and remote work areas.

“Because I was born and raised here, I like the workmanship and the culture,” he added. “The cost of living is a challenge, but this is our home, and we will always have a presence here.”

Since its founding in 1953, PTA Plastics in Oxford has transitioned from prototyping to medical device manufacturing, with a focus on employee development and upskilling.

The company has facilities in Connecticut and Colorado and for the last 13 years has been owned by its 250 employees.

“Over that period of time, we’ve transferred about $15 million worth of wealth into our employee accounts,” notes Mike Roswell, a member of the company’s senior leadership team.

“It’s a big number, and it’s been good from a company standpoint, but it’s also been good from a customer perspective—they see continuity and stability.”

Human Resources director Kelly Smith adds that the company’s job leveling program promotes career progression and development plans that enhance transparent employee growth and retention.

“PTA has an aging workforce and we need to upscale talent to get them ready for those key, critical roles that we’re looking to fill,” she said.

Friday, Oct. 17

PeterPaul Electronics in New Britain is a fourth-generation family business that specializes in manufacturing solenoid valves, serving major markets such as oil and gas, automotive, and the life sciences.

“One of the cool things about our products is that they need to be designed and engineered, and married to the applications—and that’s all very technical,” explains company president Mark Mangiafico.

“So we’re kind of an engineering playground on the application side, on the design side, and on the production side.”

Many of the engineers at the company are graduates of Connecticut schools, highlighting the company’s commitment to local education.

“Connecticut has always been the perfect home for our business,” Mangiafico says. “We originally set up here because of the strong local supply chain—everything from world-class spring manufacturers in Bristol, to rubber expertise in the Naugatuck Valley, to the machining know-how in New Britain.

“Today, we stay in Connecticut because of its highly skilled workforce, strong apprenticeship programs, and support from local universities like CCSU and UConn.”

Founded in 1850, New London-based Sheffield Pharmaceuticals manufactures and distributes prescription, healthcare, and beauty products for the largest retailers and drug store chains in the U.S.

The company was founded by Washington Wentworth Sheffield, a dental surgeon who invented modern toothpaste in the 1870s—and, with the help of his son, Lucius Sheffield, was also the first to put toothpaste in collapsible tubes.

Today, Sheffield Pharmaceuticals produces toothpaste, creams, ointments, and nasal sprays. It also generates its own power using two generator sets and recovers heat for steam and processing.

“Connecticut has a quality of life second to none,” says president and CEO Jeffrey Davis. “Our schools and universities, access to recreation, and close proximity to world-class cities like New York and Boston give Connectuicut residents opportunities and experiences that are unique and compelling.

“Our skilled labor force provides support for the manufacturing industry that is difficult to match in other parts of the country.”

With just over 600 employees, Whelen Engineering Company, Inc. in Chester manufactures high-quality electronic sirens and lighting solutions for emergency vehicles.

Whelen Engineering stands out because of its innovative approach to safety lighting and its commitment to quality control.

“From emergency vehicles on the ground to airplanes in the sky, our lights, sirens, and safety solutions are trusted when lives are on the line,” said president and CEO Geoff March.

“Whelen counts on Connecticut’s highly skilled workforce and advanced manufacturing ecosystem to design, develop, and build to the highest standards.”

Vinal Technical High School in Middletown has been part of the Connecticut Technical Education and Career System since 1961, serving students from across the state.

The system’s programs are designed to prepare students with both the academic knowledge and technical skills necessary to enter directly into the workforce or continue their education.

The school supports Connecticut’s manufacturing sector in a number of ways, including comprehensive precision machining technology and manufacturing programs that are aligned with industry needs.

Through a work-based learning program, students gain hands-on experience with local manufacturers while still in school, strengthening the pipeline between education and industry.

During the past decade, enrollment in Vinal Tech’s machining and manufacturing pathways has steadily grown, driven by demand for skilled workers in the aerospace, medical, and advanced manufacturing sectors.

The 2025 Manufacturing Tour was made possible through the generous support of CONNSTEP, Walmart, Connecticut State Community College, Connecticut Office of Manufacturing, Chelsea Groton Bank, CBIZ, and J. Morrissey, with additional support from Niagara, David Alan Hospitality Group, and Severance Foods.

RELATED

EXPLORE BY CATEGORY

Stay Connected with CBIA News Digests

The latest news and information delivered directly to your inbox.